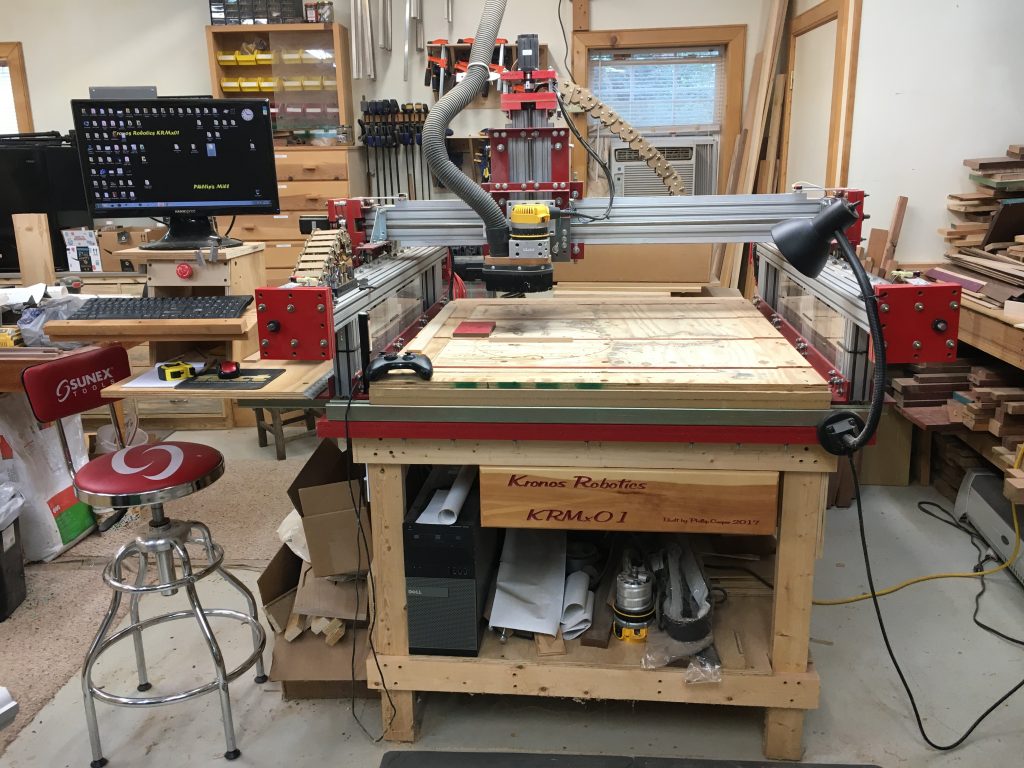

More and more shops are including a CNC machine, however not many have one that was made onsite. I priced a Shop-Bot in 2015 ($13,000), and decided that either I make one or give up on having one. I found Kronos Robotics in a web search and found the CNC build project given was something I could manage. After pricing all the materials, I figured that $3,000 was a much more managible number for me, including everything needed to make parts. I modified a few things along that I felt might be an advantage to me, and the very first run was successful. I use V-Carve Pro and Mach 3 which is very easy to learn and not resource taxing so far as the compute goes. I have updated the machine since this picture was made. One of the best changes was the guide rails, I went from v-bearings to a rail and block system, much more stable and far less maintenance. I’ve changed the spoil board three times since the machine was constructed using Baltic Birch plywood, I get over a year of use out of that before I feel the need to replace it.