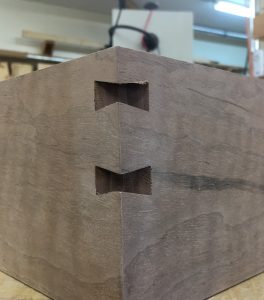

In the case construction posts we use splines that are placed into dovetail cut slots. These are designed to strengthen the miter joint that is glued, and also has thin stock, so there’s not a lot of glue area. While there is a bit of glue along the board inside the dado slots, the miters need some help. They also look very plain to me, so I want to dress them up some, and a dovetail looks nice.

A side note, with the Incra Jig tools we can do what is known as a double dovetail, which is a dovetail inside a dovetail, and using contrasting wood makes a very unique look, but our material here is so small, I don’t want to try that trick with this.

We’re going to do a single dovetail, like the one shown in this example.

This is not the actual case we’re working with in our backgammon boxes, but will do for an example here. We will cut those in another blog thread. Next we need to make the spline stock to insert into this, and we need some measurements to know how big to make our stock. Make SURE to use the same bit that cut this slot to make your spline stock, as bits can vary in degrees slightly. A 14 degree dovetail bit might actually be something slightly more or less than 14 degrees, so matching angles is critical for a good fit.

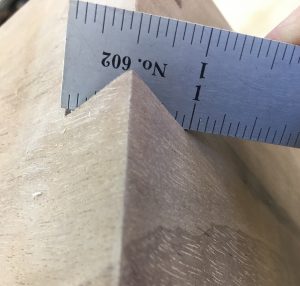

We need to cut some stock that is wide enough to make the spline key, but not too wide. We are going to set up our bit to cut 1/2″ deep, and sneak up on the fit for width, cutting a little bit at a time.

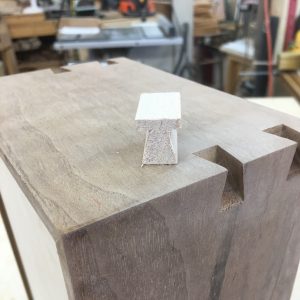

Notice the width of my raw stock, this was planed to thickness and measured carefully to ensure consistency with all blanks I make.

Here is a video clip that shows me cutting the stock on my router table.

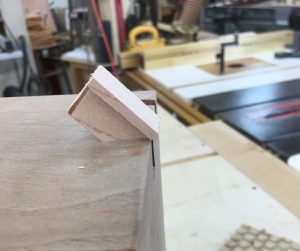

The end result should be small keys that look like these.

When we have enough of these made, we’ll glue them into place and then cut off the extra material on the band saw, and smooth them to the case using a belt sanding tool, but NOT a handheld belt sander. The case construction post will show you how to deal with finishing these spline pieces. When done, we need long stock pieces that we can cut to length, and the length needs to be about 1 1/8″, the actual spline pocket is about 1″ long, and the piece needs to be slightly taller than the dovetail cut, something to keep the dovetail piece strong while driving it into the spline slot. These should fit somewhat tight, but if they’re too tight, you can sand them using a narrow belt sanding station or by hand if you are careful to not change the profile of the angles. If they are too tight, the case will split and ruin the casework we worked so hard to create.